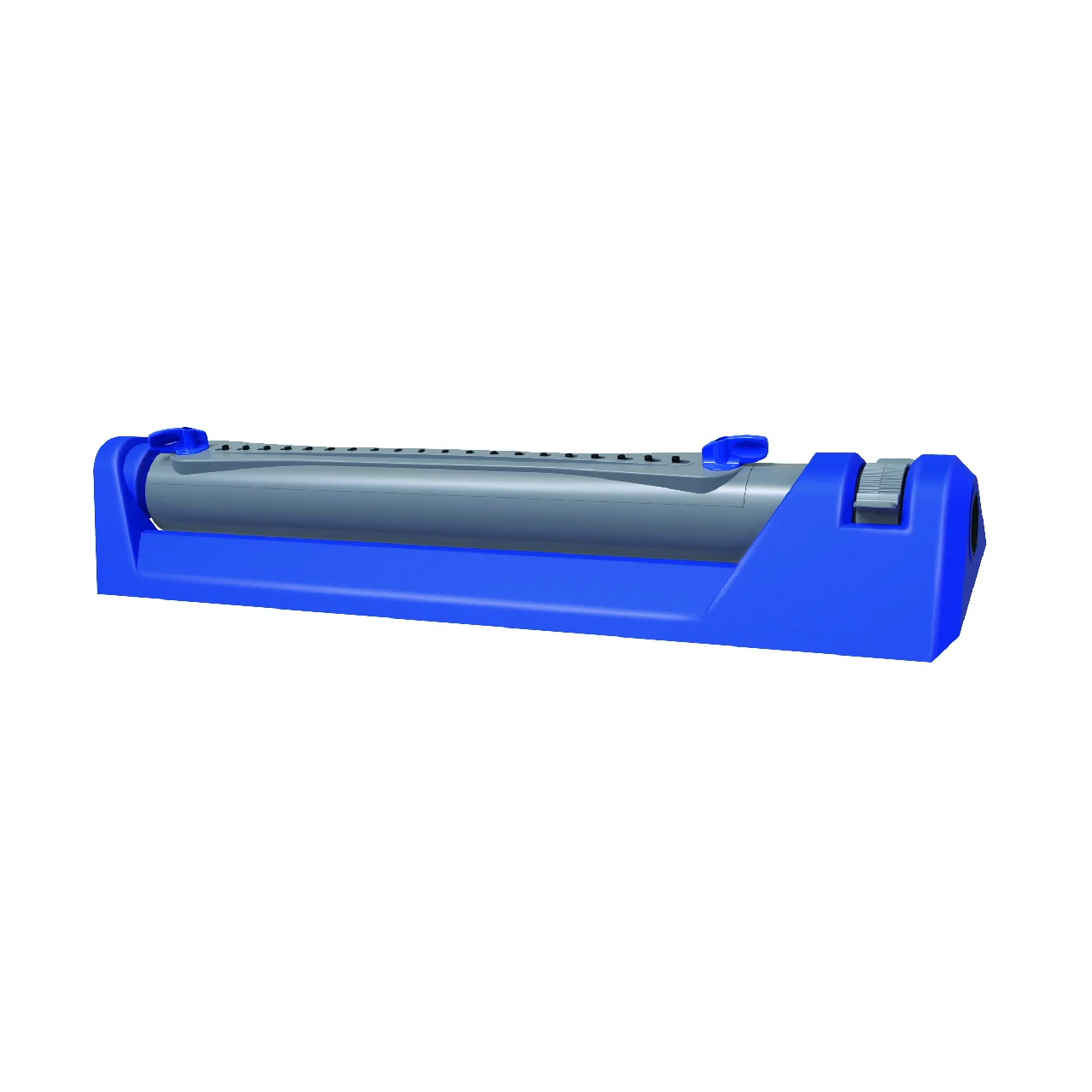

stainless spray nozzle

The stainless spray nozzle represents a pinnacle of precision engineering in fluid delivery systems. Crafted from high-grade stainless steel, these nozzles deliver exceptional performance in various industrial and commercial applications. The nozzle's design incorporates advanced fluid dynamics principles to ensure optimal spray patterns and droplet distribution, making it ideal for diverse operations from cleaning to cooling processes. The robust stainless steel construction provides outstanding resistance to corrosion, chemical exposure, and extreme temperatures, ensuring longevity in challenging environments. These nozzles feature adjustable spray patterns, allowing users to customize the flow from fine mist to powerful jet streams, adapting to different application requirements. The precision-engineered orifice design maintains consistent flow rates and uniform coverage, while the self-cleaning mechanism reduces maintenance needs. Modern stainless spray nozzles often include innovative features such as quick-connect systems for easy installation and removal, anti-clogging designs, and optimized pressure distribution channels that enhance overall performance efficiency.